RECUBE

Ventilation for printing machinery, lamination machinery, coating machinery and for the Printing & Converting sector.

Markets

Ventilation for flexographic printing press

The double fan RECUBE ventilation system allows to feed circuits and drying hoods for flexography machines in the ventilation tunnel part, the central drum part. It’s ideal for the ventilation of stack type printing machines as well.

The functioning of the ventilation for flexography printing presses: the ventilation of drying tunnels

To effectively ventilate a flexography ventilation tunnel, the RECUBE ventilation unit is equipped with two industrial fans, one of which is an outlet fan and the second one is an intake fan. A two-valve circuit allows to determine the amount of recirculated and emitted air. The portion emitted outwards has a pressure given by the suction fan of 50 mmH20.

The functioning of the ventilation for flexography printing presses: the ventilation of the drum

To effectively ventilate the drum of a flexography printing press, the double fan RECUBE ventilation unit has an outlet fan for feeding the drum cassettes and a similar one for pressuring type, for the suction of air from the drum ventilation cassettes, with a greater portion to recover the air with solvent.

The functioning of the ventilation for flexography printing presses: the ventilation of stacks

The cassette stacks can be fed by this type of ventilation unit for PRINTING & CONVERTING.

The functioning of the ventilation for flexography printing presses: the ventilation of VOC areas

The RECUBE patent is registered in Italy and Germany.

Ventilation for Rotogravure Presses

The ventilation system for rotogravure presses provides requires an outlet ventilation system on the ventilation nozzles, on the drying hoods, and on the floating or semi-floating ventilation systems, both straight and humpbacked, with lastly the possibility of ventilating with fans that blow at two different temperatures as well. The RECUBE H Easy Two ventilation unit allows (with a simple and inexpensive construction) to ventilate the rotogravure presses at operating temperatures and insulations suitable for the rotogravure environment.

Ventilation for Roller Spreaders

The ventilation for roller spreaders provides high-speed ventilation on the nozzles at temperatures that reach the values required by this field which are 200°C. The double fan ventilation unit provides ventilation with an outlet fan on the blowing drying hood and s drying ventilation with the other fan, with a greater share of air intake from the outside in order to put the drying hood in a vacuum.

Ventilation for coating machinery

The ventilation for the coating machines allows to generate (thanks to the double fan RECUBE) an outlet ventilation and intake ventilation with the possibility of recirculating the exhausted air, at a higher capacity than that the air sent, thanks to the valve system present on the machine.

Ventilation for laminating machinery

The ventilation for laminating machines with RECUBE technology allows to obtain effective ventilation with an outlet fan and an intake fan combined with a valve system to keep the drying hood in a vacuum and to allow expel the exhausted air.

Series Products

| General attachment: RECUBE Brochure | Flyer RECUBE | |||

|---|---|---|---|

| Series | Photo | Description | Attachment |

| Single Fan Horizontal Series |  |

Ventilation system with a single fan and valve system for recirculation with inlet filter and side valves positioned horizontally. | RECUBE Brochure |

| Single Fan Filter Horizontal Series |  |

Ventilation system with a recirculation fan positioned horizontally, recirculated air filtration, and valve system for recirculation with fresh air inlet filter and recirculated air filter. | RECUBE Brochure |

| Single Fan Vertical Series |  |

Single-fan ventilation unit with on-board valves positioned vertically. The valves are to be paired with a vacuum circuit with a central fan to create a vacuum in the drying hood with inlet filtration. | RECUBE Brochure |

| Single Fan Top Series |  |

Ventilation unit with a single fan to be placed on the ceiling of the ventilation tunnel. | Serie One Fan Top |

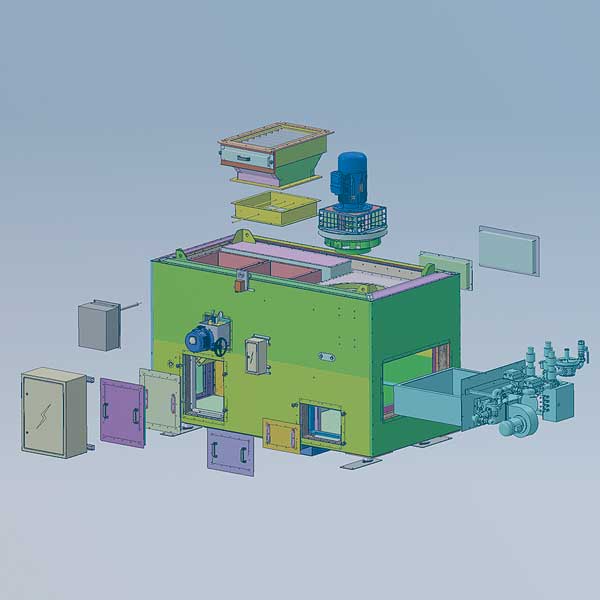

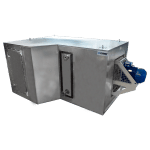

| Double Fan Series |  |

A double fan ventilation unit, with outlet and intake with valve system for recirculation with a vacuum in the drying hood with inlet filtration. | RECUBE Brochure |

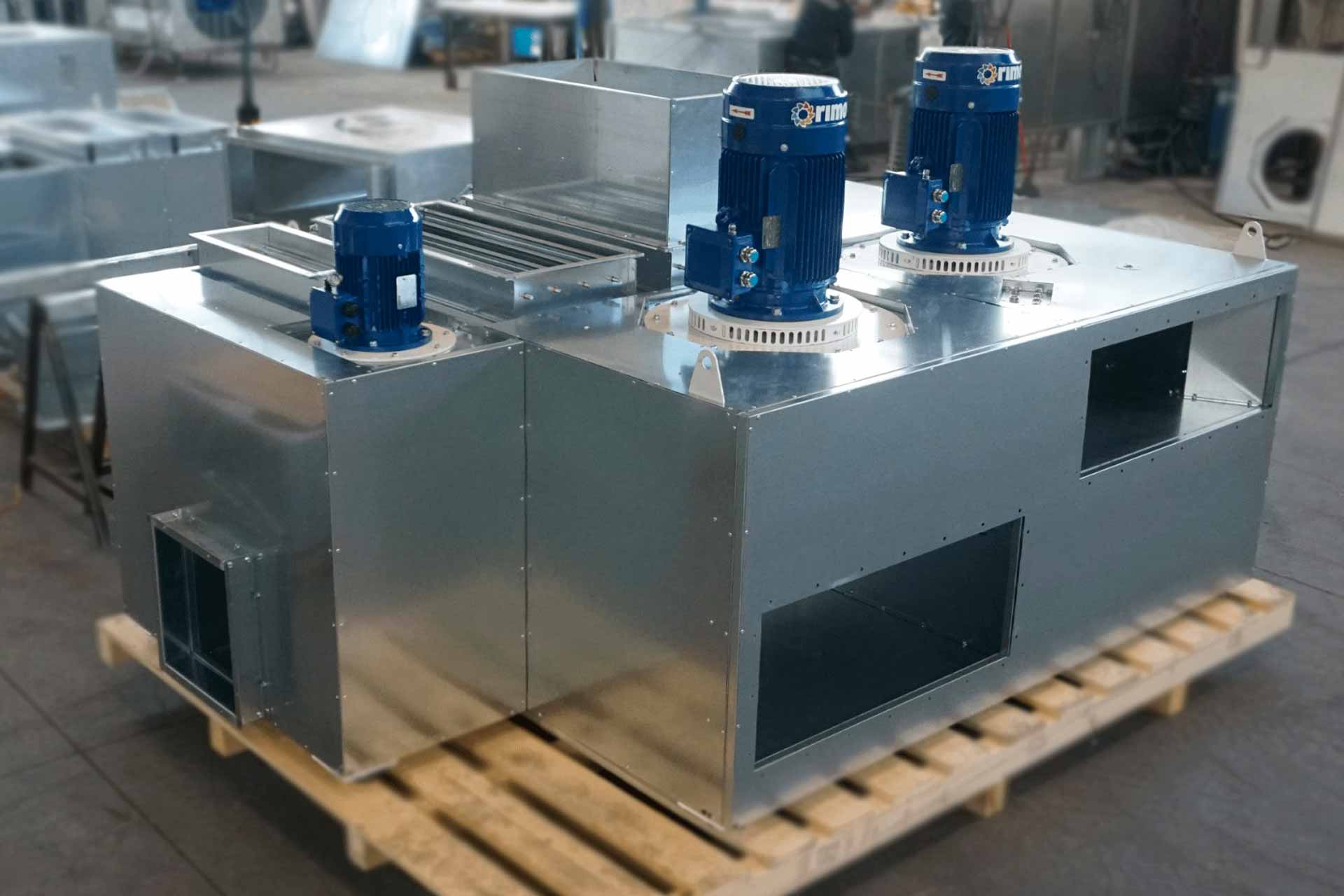

| Triple Fan Single Heating Series |  |

Ventilation unit with double outlet circuit fans and single intake circuit fan in common with a single heating. | RECUBE Brochure |

| Triple Fan Double Heating Series |  |

Ventilation system with two outlet fans, a single intake fan, and double heating in order to have two separate temperatures and with a system of modulating recirculation valves and inlet filtration. | RECUBE Brochure |

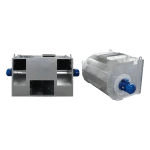

| Easy Two Series |  |

A double fan ventilation system with external heating and a type of recirculation with valves and inlet filtration. | Easy Two Series |

| H Easy Two Series |  |

A double fan ventilation system with heating on the outlet. | H Easy Two Series |

| General attachment: RECUBE Brochure | Flyer RECUBE |

|---|

| Series |

Ventilation system with a single fan and valve system for recirculation with inlet filter and side valves positioned horizontally. |

Single Fan Filter Horizontal Series Ventilation system with a recirculation fan positioned horizontally, recirculated air filtration, and valve system for recirculation with fresh air inlet filter and recirculated air filter. |

Single-fan ventilation unit with on-board valves positioned vertically. The valves are to be paired with a vacuum circuit with a central fan to create a vacuum in the drying hood with inlet filtration. |

Ventilation unit with a single fan to be placed on the ceiling of the ventilation tunnel. |

A double fan ventilation unit, with outlet and intake with valve system for recirculation with a vacuum in the drying hood with inlet filtration. |

Triple Fan Single Heating Series Ventilation unit with double outlet circuit fans and single intake circuit fan in common with a single heating. |

Triple Fan Double Heating Series Ventilation system with two outlet fans, a single intake fan, and double heating in order to have two separate temperatures and with a system of modulating recirculation valves and inlet filtration. |

A double fan ventilation system with external heating and a type of recirculation with valves and inlet filtration. |

A double fan ventilation system with heating on the outlet. |

Custom Made

Accessories

| Accessory | Photo | Description | Attachment |

|---|---|---|---|

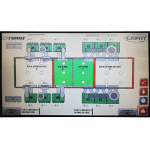

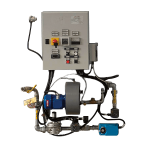

| Recube Control Drive |  |

The PLC (Programmable Logic Controller) is a digital device or system that uses a programmable memory to store information or instructions, designed to perform specific functions for the management of machines and processes. | Control Drive Brochure |

| Inverter |  |

The inverter is a voltage and frequency converter capable of creating a three-phase system controlled in voltage and frequency, to make it possible to change the speed of three-phase asynchronous motors or vector motors. | Inverter price list Inverter Brochure |

| Sampling system with LEL sensor |  |

An instrument that allows the control and measurement of three parameters: temperature, humidity (in case of processes involving water and steam) and the LEL (lower explosive limit) in case of usage of solvents that can be subject to combustion. | Request Info |

| Humidity sensor |  |

An instrument used for the measurement of humidity. | Request Info |

| Pressure sensor |  |

An instrument used for the measurement of pressure. | Request Info |

| Temperature sensor |  |

An instrument used for the measurement of the temperature. | Request Info |

| Gas Burner – Recube Burner |  |

Direct gas burners or indirect burners with combustion chambers are extremely precise heating solutions. | Request Info |

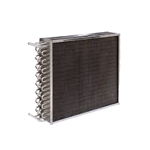

| Oil battery |  |

An instrument made up of piping, which is crossed by oil. The function of the oil is to heat the air passing through the instrument to the desired temperature. | Request Info |

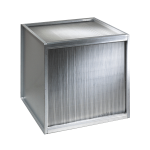

| Electrical battery |  |

An instrument with electrical resistances inside, which when powered, heat the air passing through the battery, to the desired temperature. | Request Info |

| Heat recuperator |  |

Air/air heat recovery units are heat exchange systems where a hot fluid is passed through a group of aluminum winglets which are in contact with a cold circuit in which a fluid to be heated is passed through. | Request Info |

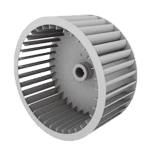

Impellers

| Impeller | Photo | Description | Attachment |

|---|---|---|---|

| RRM Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of dust, fumes, and materials in general mixed with air. These impellers are also characterized by a very flat, absorbed power curve, which doesn’t overload the motor even when operating with open outlets. | RRM Series |

| RRB Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of clean or slightly dusty air in ventilation, suction, cooling, drying, and fume elimination systems. Moreover, these impellers are ideal for all those applications where the transport of air with low pressures is necessary. | RRB Series |

| RRU Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of dust, fumes, and materials in general mixed with air. These impellers are also characterized by a very flat, absorbed power curve, which doesn’t overload the motor even when operating with open outlets. | RRU Series |

| RPA Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of clean or slightly dusty air in ventilation, suction, cooling, drying, and fume elimination systems. Moreover, these impellers are ideal for all those applications where the transport of air with low pressures is necessary. | RPA Series |

| RRT Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of dust, fumes, and materials in general mixed with air. These impellers are also characterized by a very flat, absorbed power curve, which doesn’t overload the motor even when operating with open outlets. | RRT Series |

| RRP Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of dust, fumes, and materials in general mixed with air. These impellers are also characterized by a very flat, absorbed power curve, which doesn’t overload the motor even when operating with open outlets. | RRP Series |

Motors

| Poles | Energy Efficiency | Regulations | Attachment | |

|---|---|---|---|---|

| 2-4-6 | IE2-IE3-IE4 | CSA, UL, NEMA, EAC | Request Info | |

| Specifications | |

|---|---|

| Poles | 2-4-6 |

| Energy Efficiency | IE2-IE3-IE4 |

| Regulations | CSA, UL, NEMA, EAC |

| Attachement | Request Info |

Insulation

| Type | Description | Attachment | |

|---|---|---|---|

| Class 1 | Thermal insulation for an environment with operating temperatures up to 60 ° C | Request Info | |

| Class 2 | Thermal insulation for an environment with operating temperatures within a range of 125-150° C. | Request Info | |

| Class 3 | Thermal insulation for an environment with operating temperatures within a range of 155-200° C. | Request Info | |

| Class 4 | Thermal insulation for an environment with operating temperatures within a range of 205-250° C. | Request Info | |

| Class 5 | Thermal insulation for an environment with operating temperatures within a range of 255-300° C. | Request Info | |

| Class 6 | Thermal insulation for an environment with operating temperatures within a range of 305-350°C. | Request Info | |

| Class 7 | Thermal insulation for an environment with operating temperatures within a range of 355-400°C. | Request Info | |

| Other classes of insulation for different temperature ranges (different from the one indicated above) are available on demand. | |||

| Type | Description |

|---|---|

| Class 1 | Thermal insulation for an environment with operating temperatures up to 60°C. |

| Class 2 | Thermal insulation for an environment with operating temperatures within a range of 125-150°C. |

| Class 3 | Thermal insulation for an environment with operating temperatures within a range of 155-200°C. |

| Class 4 | Thermal insulation for an environment with operating temperatures within a range of 205-250°C. |

| Class 5 | Thermal insulation for an environment with operating temperatures within a range of 255-300°C. |

| Class 6 | Thermal insulation for an environment with operating temperatures within a range of 305-350°C. |

| Class 7 | Thermal insulation for an environment with operating temperatures within a range of 355-400°C. |

| Other classes of insulation for different temperature ranges (different from the one indicated above) are available on demand. | |

Company Headquarters

Headquarters and production site on an area of over 4,000 m².

Engineering

The design and performance are certified by CFD simulations and FEM analysis, carried out by Rimor’s engineering office.

3D Design

3D design with the latest generation software and directly connected to the production machines.

Production

Production is entrusted to the qualified internal staff, employed in the use of cutting-edge machinery.

Series Production

Rimor guarantees a series production capacity that can meet the demands of large industrial groups as well.

On-site Commissioning

Rimor offers final commissioning services at customer sites (in both Italy and abroad) with results verification.

Certified Product

In addition to being patented, the RECUBE product has a series of certifications that guarantee its reliability and quality.

Custom Made

Each product is highly customizable on customer demand in accordance with its needs.

Features

RECUBE P&C Products

Single Fan Horizontal Series

RECUBE fans for Printing & Converting

Ventilation system with a single fan and valve system for recirculation with inlet filter and side valves positioned horizontally.

The RECUBE industrial fan with an integrated heating system is a “Plug & Play” monobloc solution.

The innovation of the RECUBE system allows for the reduction of ducts and encumbrances, with the integration of insulation that allows for thermal insulation and reduction of noise emissions.

The system is designed and developed for quick installation.

The innovative RECUBE patent allows the unit to be highly soundproof.

The dimensions and features of each model are customizable.

Attachement

Single Fan Filter Horizontal Series

RECUBE fans for Printing & Converting

It is a ventilation system with a recirculation fan positioned horizontally and recirculated air filtration. All paired with a valve system for recirculation with inlet filter for fresh air and filter for recirculated air.

The RECUBE industrial fan with an integrated heating system is a “Plug & Play” monobloc solution.

The innovation of the RECUBE system allows for the reduction of ducts and encumbrances, with the integration of insulation that allows for thermal insulation and reduction of noise emissions.

The system is designed and developed for quick installation.

The innovative RECUBE patent allows the unit to be highly soundproof.

The dimensions and features of each model are customizable.

Attachement

Single Fan Vertical Series

RECUBE fans for Printing & Converting

The RECUBE Single Fan Vertical Series, a soundproof and insulated fan, allows to solve the problems of heating and air filtration. The RECUBE can easily integrate:

- filters;

- steam based heat exchangers;

- hot water based heat exchangers;

- oil based heat exhangers;

- gas burners for heating and drying.

The RECUBE itself can also solve cooling problems by easily integrating chilled water and glycol water based heat exhangers.

The RECUBE Plug Fan is an industrial fan that allows to integrate regulation valves to create simple heating circuits even with multiple inputs, thus allowing the recirculation of the heated air in industrial furnaces, in drying systems for powder and liquid based paint and in heating and tempering systems.

Rimor’s RECUBE plug fan, complete with soundproof and insulation can also accommodate cross flow recuperators, flow rate control and measurement systems (a patented Venturi system for the measurement of flow rate and pressure and it is easily integrable with the regulation inverter).

Attachement

Single Fan Top Series

RECUBE fans for Printing & Converting

Ventilation unit with a single fan to be placed on the ceiling of the ventilation tunnel.

The RECUBE industrial fan with an integrated heating system is a “Plug & Play” monobloc solution.

The innovation of the RECUBE system allows for the reduction of ducts and encumbrances, with the integration of insulation that allows for thermal insulation and reduction of noise emissions.

The system is designed and developed for quick installation.

The RECUBE ventilation unit can be used at low-temperatures during heating phases and with adequate insulation solutions, at high temperatures up to 900°C.

Moreover, the patented RECUBE ventilation system is used in industrial painting processes and heating processes for thermal processes.

The RECUBE patent allows the unit to be highly soundproof with emissions of less than 70dB at 1 meter of distance.

The dimensions and features of each model are customizable.

The ventilation unit has been developed so that it can guarantee a reduced footprint and allow for positioning in spaces with limited height.

Attachement

Double Fan Series

RECUBE fans for Printing & Converting

The soundproof insulated industrial fan Rimor RECUBE with two fans creates a simple circuit that sends air to the input, recovers it and substitutes a part of it with fresh air using a heat recuperator for heat recovery and transfer. It is used mainly wherever there is a need for ventilation for dryers, ventilation for printing & converting systems, ventilation for lamination, ventilation for flexography, ventilation for rotogravure, ventilation with gas or other heating burners, ventilation for drying chambers, ventilation for furnaces with pollutants to be disposed of, or solvents to be evaporated. It is ideal for creating ventilation systems for painting with heating and integrated LEL control with solvent or humidity measurement devices inside the system.

The RECUBE plug fan constitutes a circuit of soundproof and insulated industrial fans with an inverter.

The RECUBE plug fan by Rimor can accomodate heaters and heat exchangers to generate hot or cold air, controlled with specific tools such as the inverter and regulation systems such as valves.

Attachement

Triple Fan Single Heating Series

RECUBE fans for Printing & Converting

The RECUBE Triple Fan Single Heating Series with double launch, single suction with single heating and fresh air intakes allows to minimize the components while obtaining the desired circuit. The objective to be reached with the desired circuit is to have two different launch temperatures and two different flows, a single suction, an area of choice where the exhausted air (controlled through humidity or temperature sensors) is replaced with fresh air, a single heating and subsequently two air intakes that lower the temperature of the flow that has to be kept at a lower temperature between the two.

The RECUBE soundproof and insulated ventilation system allows for a very effective configuration by minimizing the humidity control systems, LEL control systems, and heating systems while at the same time achieving a double launch circuit at different temperatures and a single intake on gravure hoods, dryers, flexographic hoods or lamination, and coating machinery.

Attachement

Triple Fan Double Heating Series

RECUBE fans for Printing & Converting

The RECUBE Triple Fan Double Heating Series ventilation unit with double launch and single intake with double heating allows to obtain a typical circuit where there are two launching machinery with two different inputs such as air blades or dryers for rotogravure machinery, flexographic machinery, lamination machinery, lamination, and coating machinery. These are examples of inputs where there are two air-launch areas and a single intake with subsequent choice of emission of exhausted air to the outside and automatic intake through filters, necessary to restore the quota of exhausted air emitted.

The RECUBE plug fan ensures considerable flexibility as the double heating system allows to obtain two different temperatures on the two airflows. This industrial fan model is soundproof and insulated and this ensures effective circuit management.

The RECUBE Plug Fan ventilation unit with double launch and single suction with double heating solves the problems of drying, management of two areas in depression and heating and launch at different temperatures and single-suction through one industrial fan.

Attachement

Easy Two Series

RECUBE fans for Printing & Converting

The RECUBE Easy Two is the ideal solution for circuits with 0-100% recirculations with external heating.

The basic heating is downstream of the launch fan to optimize the heating in non-insulated solutions at lower temperatures.

The special valve system allows to optimize production spaces and costs, making it a smart solution for every situation.

The range is complete from diameter 350 to diameter 500 with coverage of all the most important flow rates for this sector.

The ventilation unit features a special acoustic housing for the impeller with rectilinear elements, a distinctive feature of the Rimor patent, where the rectilinear sections manage to absorb the acoustic waves at every frequency making the machine soundproof.

Attachement

Serie H Easy Two

RECUBE fans for Printing & Converting

The RECUBE H Easy Two is the ideal solution for circuits with 0-100% recirculations with external heating.

The basic heating is downstream of the launch fan to optimize the heating in non-insulated solutions at lower temperatures while the solution with integrated heating is ideal for insulated situations at higher operating temperatures.

The special valve system allows to optimize production spaces and costs, making it a smart solution for every situation.

The range is complete from diameter 350 to diameter 500 with coverage of all the most important flow rates for this sector.

The ventilation unit features a special acoustic housing for the impeller with rectilinear elements, a distinctive feature of the Rimor patent, where the rectilinear sections manage to absorb the acoustic waves at every frequency making the machine soundproof.

Attachement

Other Solutions

Revamping for printing machinery

RECUBE fans for Printing & Converting

The standard RECUBE series can be used to achieve an optimal result and an increase in efficiency during the revamping, regeneration process, or when the objective is to replace the ventilation system with other more modern, up to date ventilation systems for rotogravure machinery, flexography machinery, laminators or in general for the Printing and Converting sector.

Rimor’s RECUBE ventilation units for Printing & Converting can satisfy various needs, such as those related to only the intake of the drying hoods or those related to both the outlet and the intake. The ventilation units can also transform circuits that do not mix and replace exhausted air with fresh air, with systems that allow it.

Performance analysis allows to choose the best ventilation solution, executed with soundproof, insulated, and high-efficiency ventilation units.

It is possible to improve and optimize any printing line with certainty.

The RECUBE, an insulated and soundproof ventilation unit, integrates systems (developed by Rimor S.r.l. with a view to Industry 4.0) which allow the customer to obtain hyper-amortization for the Printing & Converting sector onboard ventilation system.

Attachement

Drying Lines

RECUBE fans for Printing & Converting

The RECUBE is an ideal ventilation unit in its standard execution for the realization of long drying lines such as those in the coating sector.

The drying lines allow for the possibility of being inserted and configured on an existing plant. The drying lines are complete discharge systems with ducts developed to expel the exhausted gases effectively.

Rimor drying lines can be set at different temperatures and have a precise temperature management curve.

The RECUBE Dry drying hoods are connected with a particular discharge system that allows for the possibility of recovering dynamic pressure by optimally mix the air.

Computational fluid dynamics simulations and finite element analysis carried out by Rimor’s engineering department allow to manage the drying hood depression with maximum efficiency and to manage airflows achieving a result of speed and temperature with variation within a maximum range of +/-1 m/s and +/-1°C.

RECUBE Dry drying hoods can be easily lifted for maintenance and have removable nozzles that allow for the inspection and cleaning of the drying hoods.

Rimor drying lines are an ideal solution for coating lines, lamination furnaces, and laminators.