RECUBE

Soundproof and insulated industrial fans

Markets

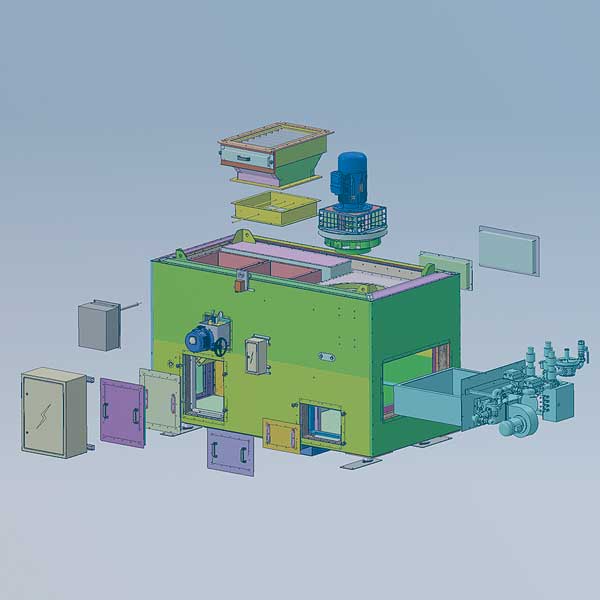

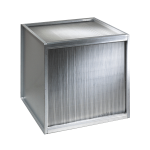

Soundproof and insulated industrial fans: the RECUBE system, The new generation of ventilation systems.

RECUBE is a new industrial ventilation system developed by Rimor S.r.l. RECUBE is a new concept of ventilation for industrial processes that involve air: a leading system recognized in many fields and industries.

The concept of the cube:

RECUBE is a compact ventilation unit, able to achieve high performances in reduced spaces. It can be assembled on the coating, rotogravure, flexography, lamination machinery, filtration systems (such as for sandblasting and painting) and allows the integration with energy recovery systems, insulation systems, solvent control systems, flow rates, and pressure control systems. It is particularly appreciated for its low noise levels and easy to carry out maintenance.

The product was under development for 6 years and was first introduced on the market in 2008, the RECUBE unit is today Rimor’s product line strong point thanks to its integration in their production lines by leading customers in their respective sectors.

Series Products

| General attachment: Brochure RECUBE | Flyer RECUBE | |||

|---|---|---|---|

| Series | Photo | Description | Attachment |

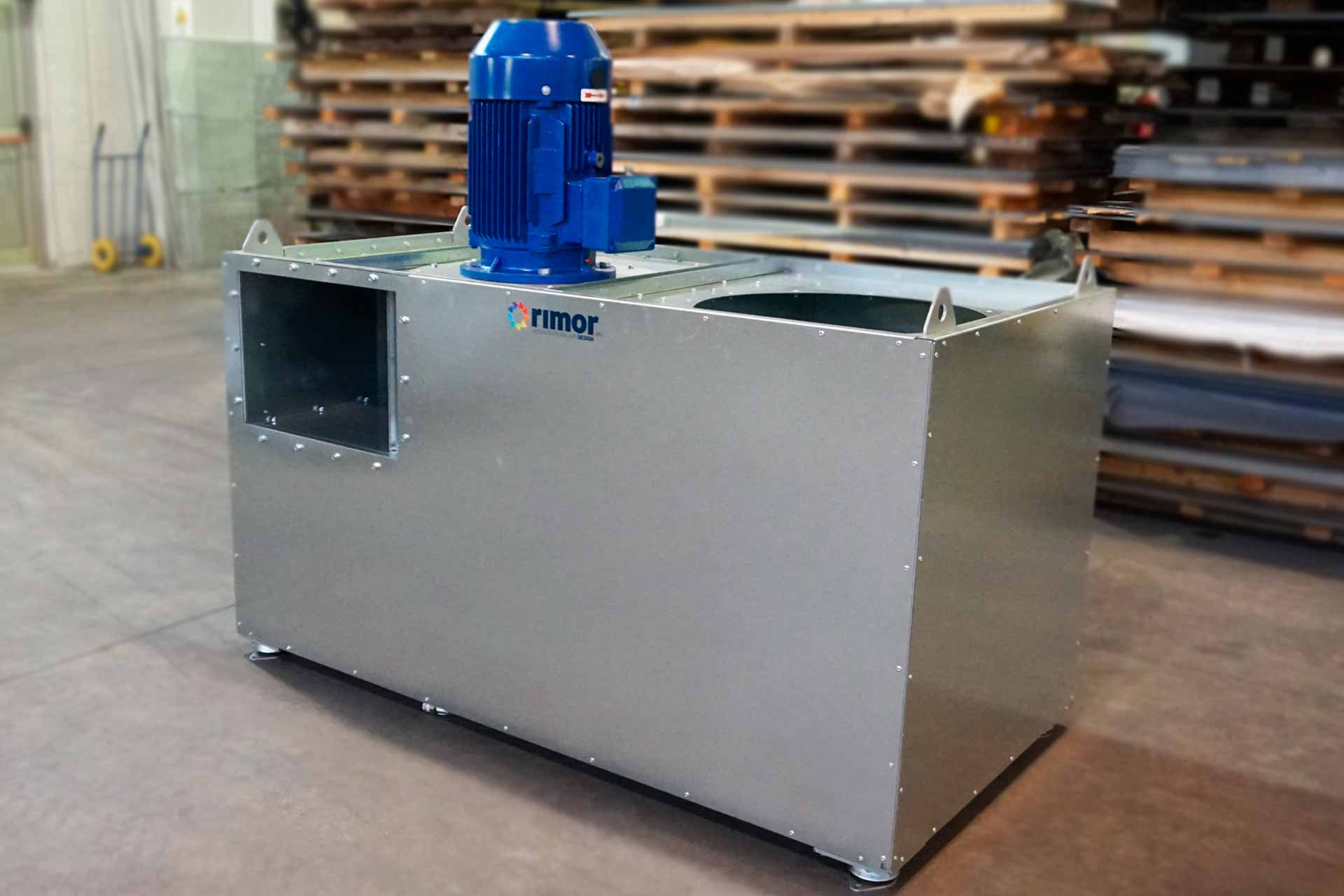

| RECUBE Plug Fan – Single Motor Fan |  |

It’s a compact single fan machine with an insulation and soundproofing option. | RECUBE Plug Fan |

| RECUBE Plug Fan Reverse – Single Motor Fan |  |

It’s a compact single fan machine for air suction from above with insulation and soundproofing option. | RECUBE Plug Fan Reverse |

| RECUBE Plug Fan Tall – Single Motor Fan |  |

It’s a compact single fan machine with the possibility of having accessories on-board machine on the suction side. Insulation and soundproofing options are available. | RECUBE Plug Fan Tall |

| RECUBE Plug Fan Blower – Single Motor Fan |  |

It’s a compact single fan machine used for cooling and with room air suction. Soundproofing and filters integration options are available. | RECUBE Plug Fan Blower |

| RECUBE Plug Fan for extraction – Single Motor Fan |  |

It’s a compact single-fan machine that can put the air in a vacuum, create a vacuum for lifting, create a vacuum in test chambers, and extraction of air at high pressures with re-emission in the work environment. Options of soundproofing and accessories integration are available. | RECUBE Plug Fan for extraction |

| RECUBE Plug Fan parallel – Double Motor Fan |  |

It’s a double fan ventilation system built in a single body with the dual possibility of creating a ventilation system with two fans in parallel or two fans in series. The options of insulation, soundproofing, and integration of accessories are available. | Brochure RECUBE |

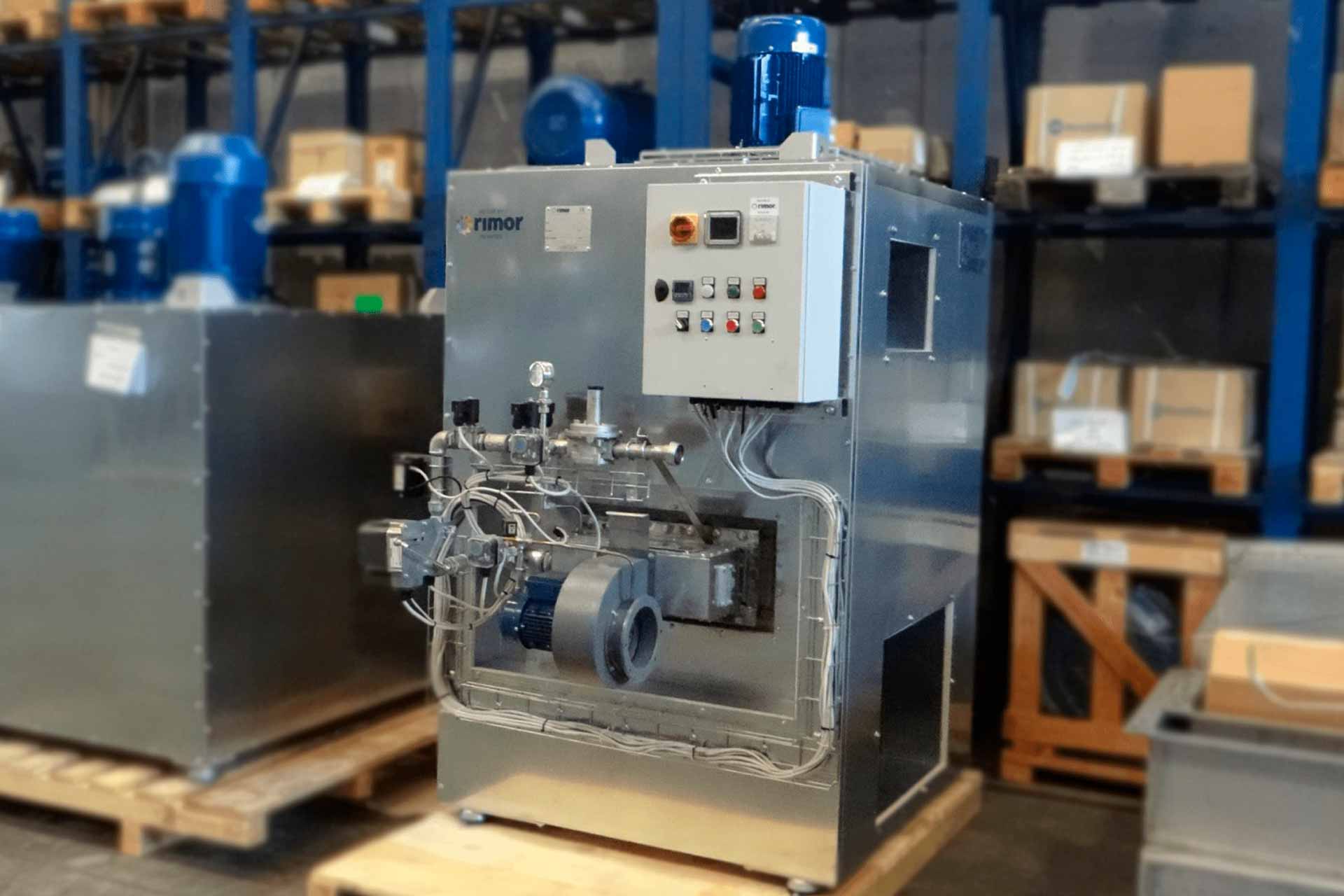

| RECUBE Plug Fan with burner – Industrial fan |  |

It’s a ventilation system with a burner for heating purposes which can be used in multiple processes. It is available as a heating machine with direct or indirect burners, with the heating system directly integrated into the ventilation machine. Options of insulation, soundproofing, and integration of accessories are available. | ECUBE Plug Fan with burner |

| RECUBE Plug Fan for furnace burners – Industrial fan |  |

It’s a ventilation system for the supply of industrial burners which finds application in the generation of combustion air flows that are conveyed to industrial burners of the non-monobloc but dissociated type. Options of soundproofing and integration of accessories are available. | RECUBE Plug Fan for furnace burners |

| General attachment: Brochure RECUBE | Flyer RECUBE |

|---|

| Series |

RECUBE Plug Fan – Single Motor Fan It’s a compact single fan machine with an insulation and soundproofing option. |

RECUBE Plug Fan Reverse – Single Motor Fan It’s a compact single fan machine for air suction from above with insulation and soundproofing option. |

RECUBE Plug Fan Tall – Single Motor Fan It’s a compact single fan machine with the possibility of having accessories on-board machine on the suction side. Insulation and soundproofing options are available. |

RECUBE Plug Fan Blower – Single Motor Fan It’s a compact single fan machine used for cooling and with room air suction. Soundproofing and filters integration options are available. |

RECUBE Plug Fan for extraction – Single Motor Fan It’s a compact single-fan machine that can put the air in a vacuum, create a vacuum for lifting, create a vacuum in test chambers, and extraction of air at high pressures with re-emission in the work environment. Options of soundproofing and accessories integration are available. |

RECUBE Plug Fan parallel – Double Motor Fan It’s a double fan ventilation system built in a single body with the dual possibility of creating a ventilation system with two fans in parallel or two fans in series. The options of insulation, soundproofing, and integration of accessories are available. |

RECUBE Plug Fan with burner – Industrial fan It’s a ventilation system with a burner for heating purposes which can be used in multiple processes. It is available as a heating machine with direct or indirect burners, with the heating system directly integrated into the ventilation machine. Options of insulation, soundproofing, and integration of accessories are available. |

RECUBE Plug Fan for furnace burners – Industrial fan It’s a ventilation system for the supply of industrial burners which finds application in the generation of combustion air flows that are conveyed to industrial burners of the non-monobloc but dissociated type. Options of soundproofing and integration of accessories are available. |

Custom Made

Accessories

| Accessory | Photo | Description | Attachment |

|---|---|---|---|

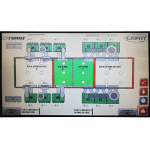

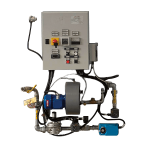

| Recube Control Drive |  |

The PLC (Programmable Logic Controller) is a digital device or system that uses a programmable memory to store information or instructions, designed to perform specific functions for the management of machines and processes. | Control Drive Brochure |

| Inverter |  |

The inverter is a voltage and frequency converter capable of creating a three-phase system controlled in voltage and frequency, to make it possible to change the speed of three-phase asynchronous motors or vector motors. | Inverter price list Inverter Brochure |

| Sampling system with LEL sensor |  |

An instrument that allows the control and measurement of three parameters: temperature, humidity (in case of processes involving water and steam) and the LEL (lower explosive limit) in case of usage of solvents that can be subject to combustion. | Request Info |

| Humidity sensor |  |

An instrument used for the measurement of humidity. | Request Info |

| Pressure sensor |  |

An instrument used for the measurement of pressure. | Request Info |

| Temperature sensor |  |

An instrument used for the measurement of the temperature. | Request Info |

| Gas Burner – Recube Burner |  |

Direct gas burners or indirect burners with combustion chambers are extremely precise heating solutions. | Request Info |

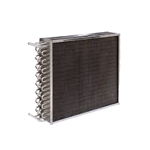

| Oil battery |  |

An instrument made up of piping, which is crossed by oil. The function of the oil is to heat the air passing through the instrument to the desired temperature. | Request Info |

| Electrical battery |  |

An instrument with electrical resistances inside, which when powered, heat the air passing through the battery, to the desired temperature. | Request Info |

| Heat recuperator |  |

Air/air heat recovery units are heat exchange systems where a hot fluid is passed through a group of aluminum winglets which are in contact with a cold circuit in which a fluid to be heated is passed through. | Request Info |

Impellers

| Impeller | Photo | Description | Attachment |

|---|---|---|---|

| RRM Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of dust, fumes, and materials in general mixed with air. These impellers are also characterized by a very flat, absorbed power curve, which doesn’t overload the motor even when operating with open outlets. | RRM Series |

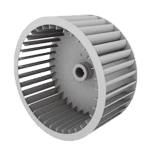

| RRB Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of clean or slightly dusty air in ventilation, suction, cooling, drying, and fume elimination systems. Moreover, these impellers are ideal for all those applications where the transport of air with low pressures is necessary. | RRB Series |

| RRU Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of dust, fumes, and materials in general mixed with air. These impellers are also characterized by a very flat, absorbed power curve, which doesn’t overload the motor even when operating with open outlets. | RRU Series |

| RPA Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of clean or slightly dusty air in ventilation, suction, cooling, drying, and fume elimination systems. Moreover, these impellers are ideal for all those applications where the transport of air with low pressures is necessary. | RPA Series |

| RRT Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of dust, fumes, and materials in general mixed with air. These impellers are also characterized by a very flat, absorbed power curve, which doesn’t overload the motor even when operating with open outlets. | RRT Series |

| RRP Series |  |

The centrifugal impellers belonging to this high-performance series are ideal for the suction of dust, fumes, and materials in general mixed with air. These impellers are also characterized by a very flat, absorbed power curve, which doesn’t overload the motor even when operating with open outlets. | RRP Series |

Motors

| Poles | Energy Efficiency | Regulations | Attachment | |

|---|---|---|---|---|

| 2-4-6 | IE2-IE3-IE4 | CSA, UL, NEMA, EAC | Request Info | |

| Specifications | |

|---|---|

| Poles | 2-4-6 |

| Energy Efficiency | IE2-IE3-IE4 |

| Regulations | CSA, UL, NEMA, EAC |

| Attachement | Request Info |

Insulation

| Type | Description | Attachment | |

|---|---|---|---|

| Class 1 | Thermal insulation for an environment with operating temperatures up to 60 ° C | Request Info | |

| Class 2 | Thermal insulation for an environment with operating temperatures within a range of 125-150° C. | Request Info | |

| Class 3 | Thermal insulation for an environment with operating temperatures within a range of 155-200° C. | Request Info | |

| Class 4 | Thermal insulation for an environment with operating temperatures within a range of 205-250° C. | Request Info | |

| Class 5 | Thermal insulation for an environment with operating temperatures within a range of 255-300° C. | Request Info | |

| Class 6 | Thermal insulation for an environment with operating temperatures within a range of 305-350°C. | Request Info | |

| Class 7 | Thermal insulation for an environment with operating temperatures within a range of 355-400°C. | Request Info | |

| Other classes of insulation for different temperature ranges (different from the one indicated above) are available on demand. | |||

| Type | Description |

|---|---|

| Class 1 | Thermal insulation for an environment with operating temperatures up to 60°C. |

| Class 2 | Thermal insulation for an environment with operating temperatures within a range of 125-150°C. |

| Class 3 | Thermal insulation for an environment with operating temperatures within a range of 155-200°C. |

| Class 4 | Thermal insulation for an environment with operating temperatures within a range of 205-250°C. |

| Class 5 | Thermal insulation for an environment with operating temperatures within a range of 255-300°C. |

| Class 6 | Thermal insulation for an environment with operating temperatures within a range of 305-350°C. |

| Class 7 | Thermal insulation for an environment with operating temperatures within a range of 355-400°C. |

| Other classes of insulation for different temperature ranges (different from the one indicated above) are available on demand. | |

Company Headquarters

Headquarters and production site on an area of over 4,000 m².

Engineering

The design and performance are certified by CFD simulations and FEM analysis, carried out by Rimor’s engineering office.

3D Design

3D design with the latest generation software and directly connected to the production machines.

Production

Production is entrusted to the qualified internal staff, employed in the use of cutting-edge machinery.

Series Production

Rimor guarantees a series production capacity that can meet the demands of large industrial groups as well.

On-site Commissioning

Rimor offers final commissioning services at customer sites (in both Italy and abroad) with results verification.

Certified Product

In addition to being patented, the RECUBE product has a series of certifications that guarantee its reliability and quality.

Custom Made

Each product is highly customizable on customer demand in accordance with its needs.

Features

RECUBE Products

RECUBE Plug Fan

Single Motor Fan

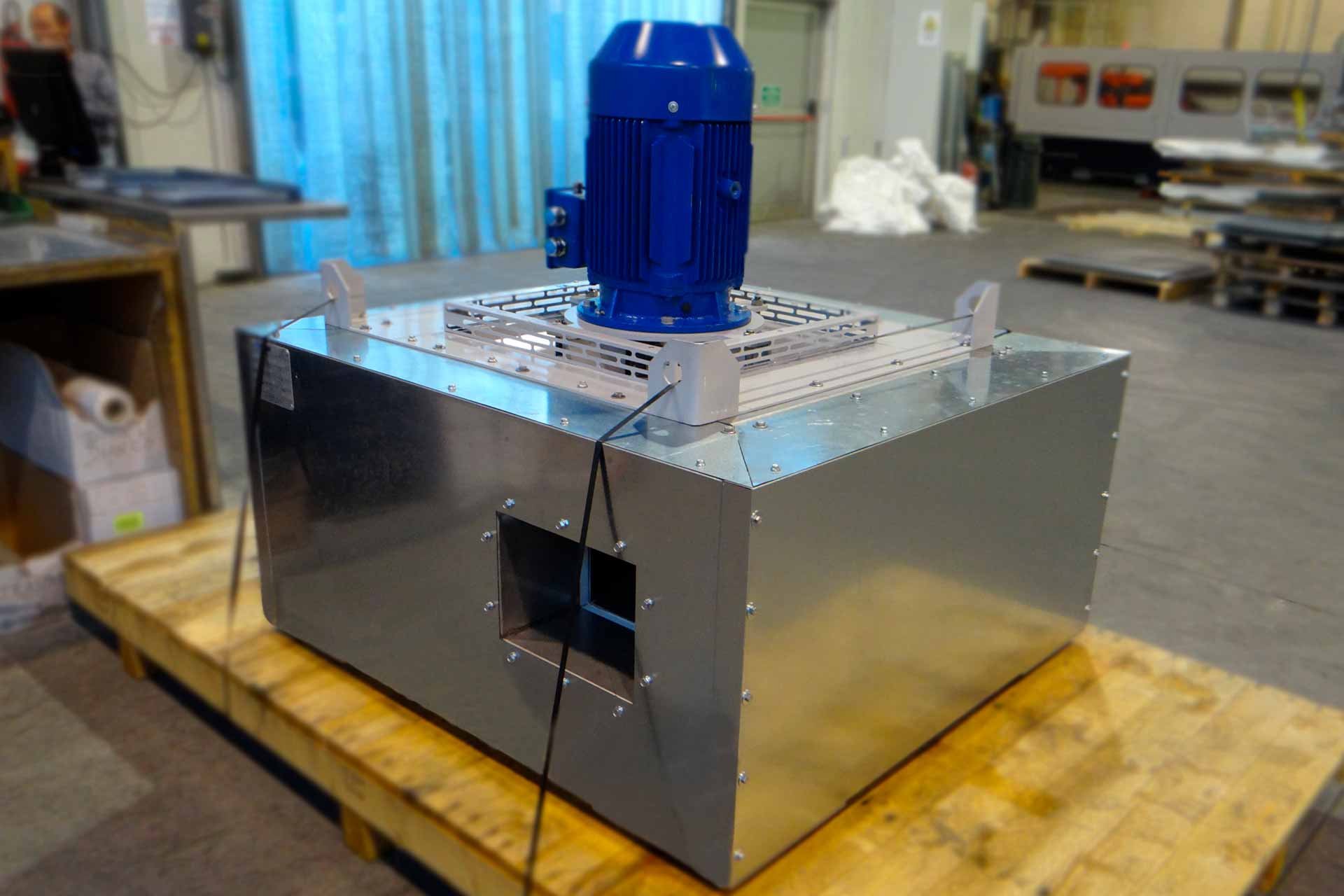

RECUBE plug fan, the patented, insulated and soundproof industrial fan is a compact unit positionable horizontally in any situation with inlet directly from the bottom side and output from the 4 sides.

RECUBE, the soundproof industrial fan is available with backward blades, forward curved blades and forward curved open blades.

It is an industrial fan that is by default soundproof and insulated. The industrial fan RECUBE an (exclusive product of Rimor) extends the lifespan of the motor bearings thanks to the vertical position of the electric motor, the minimal vibration of the industrial fan, the minimum degree of imbalance thanks to the structure of the RECUBE and the possibility of eliminating anti-vibration joints and anti-vibration mounts thanks to RECUBE’s design.

Maintenance operations such as RECUBE’s ventilation machine balancing and impeller cleaning are made easy and safe as required by the machinery directive 2006/42/CE.

Flow Rimor is available: an accessory for the fan flow rate measurement through the Venturi system.

Attachement

RECUBE Plug Fan Reverse

Single Motor Fan

RECUBE plug fan, the patented, insulated and soundproof industrial fan is a compact unit positionable horizontally in any situation with inlet directly from the bottom side and output from the 4 sides.

RECUBE, the soundproof industrial fan is available with backward blades, forward curved blades and forward curved open blades.

It is an industrial fan that is by default soundproof and insulated. The industrial fan RECUBE an (exclusive product of Rimor) extends the lifespan of the motor bearings thanks to the vertical position of the electric motor, the minimal vibration of the industrial fan, the minimum degree of imbalance thanks to the structure of the RECUBE and the possibility of eliminating anti-vibration joints and anti-vibration mounts thanks to RECUBE’s design.

Maintenance operations such as RECUBE’s ventilation machine balancing and impeller cleaning are made easy and safe as required by the machinery directive 2006/42/CE.

Flow Rimor is available: an accessory for the fan flow rate measurement through the Venturi system.

This RECUBE features the installation of the motor in a vertical position with the coupling side facing upwards to facilitate installation in cases where the aeraulic circuit enters the fan from above.

Attachement

RECUBE Plug Fan Tall

Single Motor Fan

The RECUBE plug fan tall by Rimor is a compact ventilation unit that eliminates the need to insert a suction air plenum and ducts in the inlet. The RECUBE is a soundproof and ventilation unit that also provides the option of being divided into two parallel fans (see RECUBE double fan plug).

The RECUBE plug fan mono is a soundproof and insulated ventilation unit with on-board measurement systems which allows air intake in the unit from multiple directions and serve multiple inputs and several branches of the system.

The RECUBE Plug fan is an industrial fan with an exclusive integrated soundproofing case.

Attachement

RECUBE Plug Fan Blower

Single Motor Fan

The RECUBE plug fan blower is a soundproof cooling fan with the air intake from the environment with the integration of optional filters. It is a specific model of soundproof industrial fan with an integrated silencer in the RECUBE that minimizes the overall dimensions and maximizes the efficiency and safety of the machinery.

The RECUBE plug fan Blower on vertical axis has default soundproofing with noise absorbing partitions and a further possibility of soundproofing in case it is necessary to achieve reduced acoustic emissions up to even 75 dB (A).

The RECUBE plug fan is used to cool and ventilate hot items that have to be cooled with a directly coupled ventilation unit with limited ground encumbrance.

The ventilation unit can integrate measurement and control systems for flow rate and pressure.

Attachement

RECUBE Plug Fan for extraction

Single Motor Fan

The RECUBE Plug Fan industrial fan for extraction is an industrial fan that can:

- put an input in depression to create the vacuum in production circuits (for example for deformations of metal sheet at high temperature);

- create depression in a chamber;

- suck air at high pressures to lift items;

- extraction of air with re-emission in the work environment.

For example, the RECUBE plug fan can be equipped with a silencer on the outlet section or a simple filter for re-emission in the environment.

The extraction system RECUBE plug fan is a soundproof and insulated ventilation unit that can also extract extremely hot fumes or dusty air.

Attachement

RECUBE Plug Fan parallel

Double Motor Fan

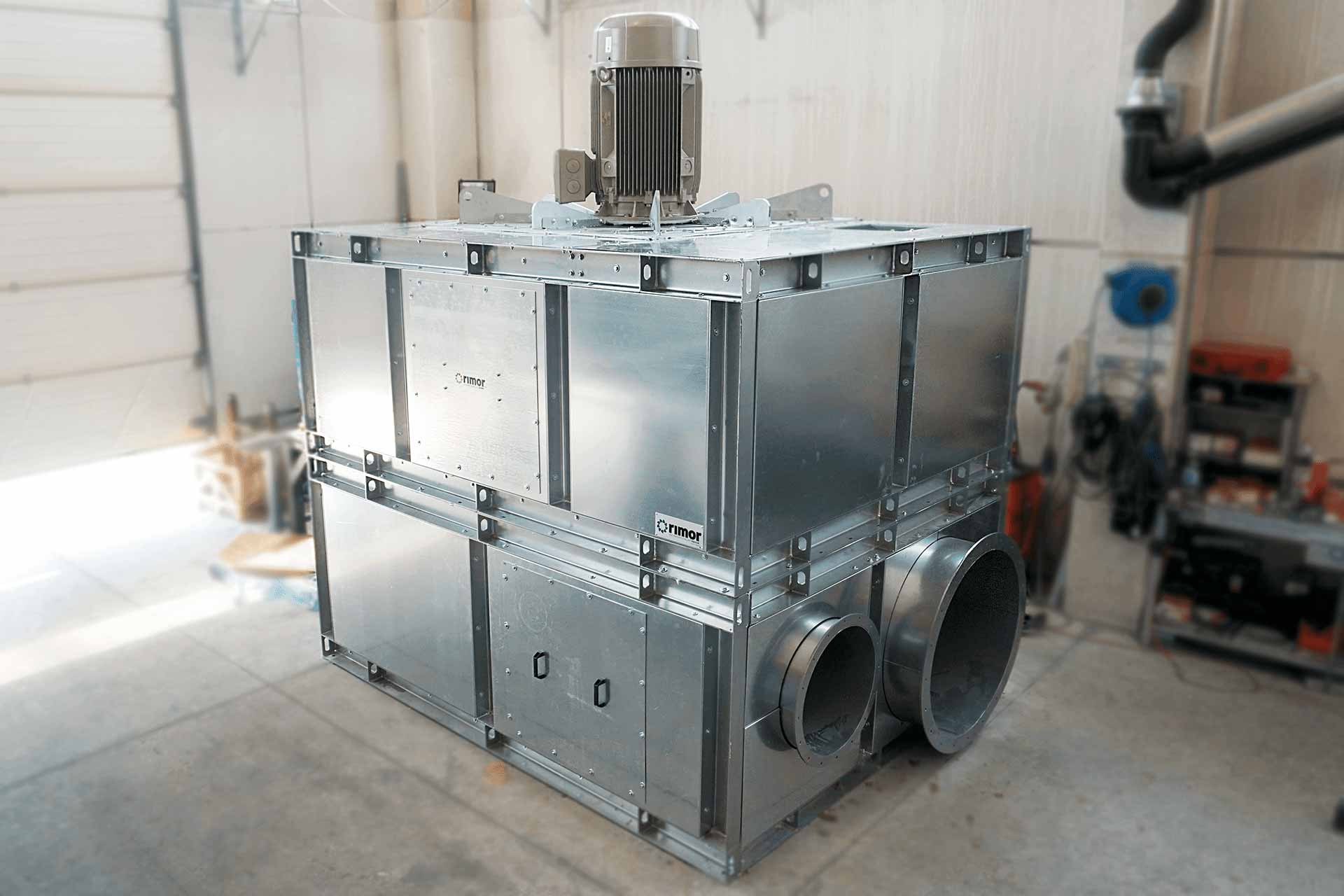

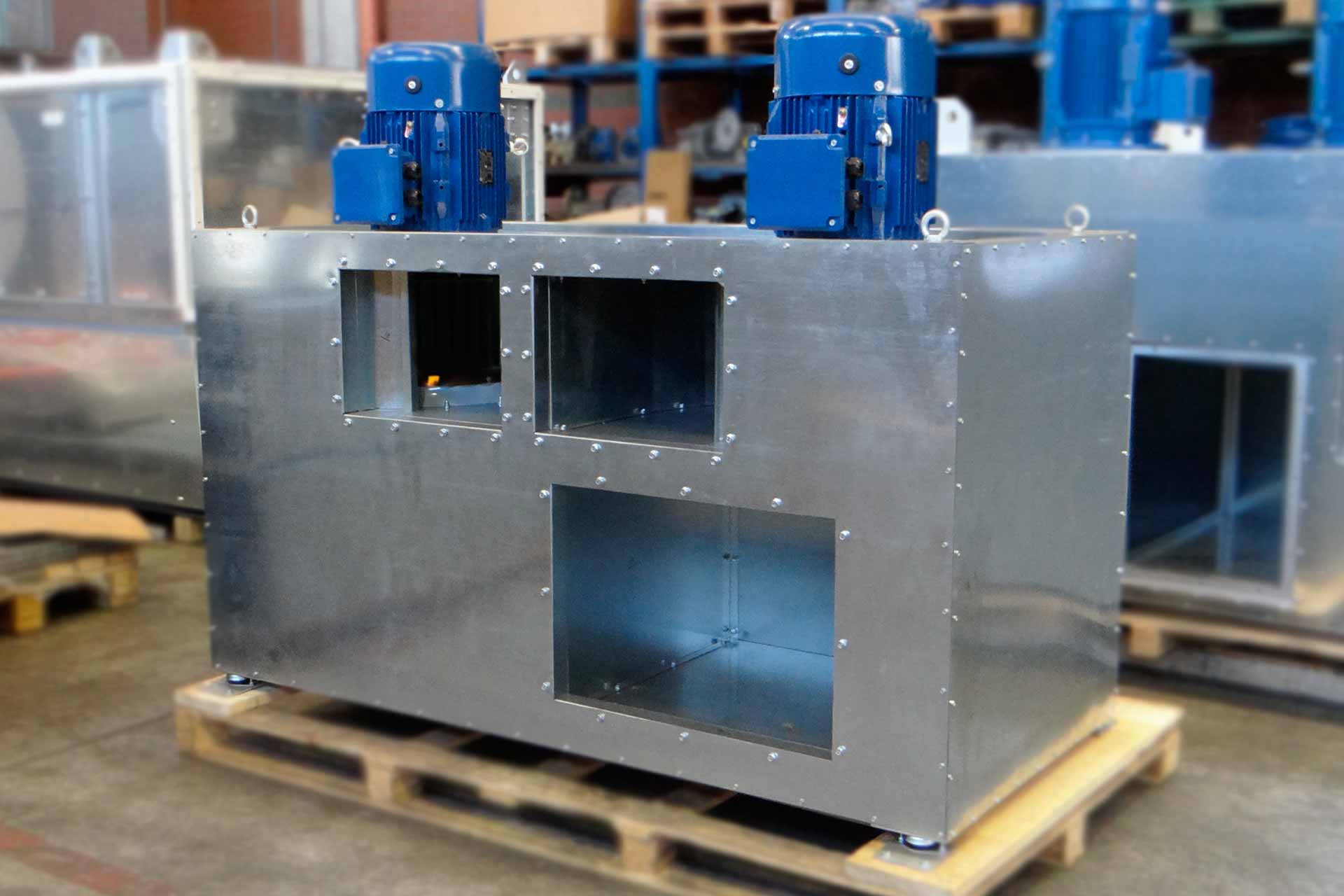

The RECUBE plug fan parallel is a two-fan ventilation system built together in the same body with the possibility of creating a system with two fans in parallel or two fans in series.

The two-fan RECUBE plug fan system is a ready-to-use system with two industrial fans installed in parallel and connected through valves. This configuration allows the use of the two industrial fans (soundproofed with integrated soundproof cabin, integrated insulation) simultaneously on the same circuit thus doubling the flow rate. An alternative configuration of the two-fan RECUBE plug fan system is that with the two fans installed in series which allows to double the pressure.

The RECUBE plug fan double allows to disassemble one industrial fan without having to stop the functioning of the other one, allowing, therefore, the maintenance of one industrial fan while the other one is operational.

The RECUBE plug fan double is a two industrial fan system configurable according to the customer requirements. The soundproof and insulated RECUBE plug fan double creates efficient circuits.

Attachement

RECUBE Plug Fan with burner

Industrial fan

The RECUBE industrial fan with industrial burner is a heating machinery that can be used in multiple processes. It is available as a heating machinery with direct or indirect burners integrated into the ventilation system.

The RECUBE heating and ventilation system is a system used for example in industrial drying or heating processes, industrial painting processes and heating processes for thermal processes.

The RECUBE ventilation and heating system is used during heating phases at low temperatures or high temperatures up to 900° C, during phases of metal tempering or preparatory phases for heating treatments.

These ventilation units can be easily integrated with the customer’s machinery and can solve heating problems in high performance industrial and environmental processes. The RECUBE offers the possibility of being equipped with valves as well as heating systems such as air vein burners or burners with heat exchanger.

It is available in the standard and custom versions. The standard product line includes a certain number of models with standard heating flow rates and outputs, usually used in industrial processes but Rimor can easily manufacture on-demand custom models for the customer.

Attachement

RECUBE Plug Fan for furnace burners

Industrial fan

The RECUBE Plug Fan for industrial burners finds application in the generation of combustion air flows conveyed to industrial burners which are not monobloc. This model, therefore, offers the possibility of having a soundproof and insulated fan to power industrial burners.

The RECUBE plug fan, an industrial fan for furnace burner is reliable, with rapid and convenient maintenance features.

The reliability of the industrial fan with burner is never put into question with the RECUBE plug fan. The possibility of combining the RECUBE with dapò valves, regulating valves, inverters, suction filters and recuperators makes it possible to create a ventilation system with simple burners -recovery or regenerative- quickly and reliably with the plug-in execution typical of RECUBES.

RECUBE plug fans for burners are flat curve to allow the best management of modulating burners.

F.G.R. Fuel Gas Recirculation Model – RECUBE Plug Fan for furnace burners with Nox reduction

During combustion at high temperature, the oxygen (O₂) and nitrogen (N₂) present in the air react and generate NOx nitrogen oxides which are responsible for many polluting phenomena such as acid rain and the formation of ozone in the lower atmosphere, with known detrimental health consequences.

The RECUBE plug fan for burners integrates an external fumes recirculation fan to reduce the flame temperature, the oxygen concentration and raise the aggregates (N₂ and CO₂).

Model with Filter – RECUBE Plug Fan for furnace burners with filter

This RECUBE plug fan model for burners that includes a filter is a series of soundproof and insulated fans with reduced acoustic emission and filters on the suction side in pre-filter and fine filtration with soundproofing of the input area.